India’s Used Oil Re-Refining Revolution: Hydrotreating & Vacuum Distillation in 2025

Author Name

Dhairya Gandhi

Date Published

16 December 2025

India produces over 1.3 million tonnes of used lubricating oil annually, making re-refining a vital part of the country’s environmental and industrial ecosystem. With the rise of EPR regulations, sustainability targets, and the demand for high-quality lubricants, India is rapidly transitioning to modern re-refining technologies. The most advanced among them is the integrated system of Advanced Vacuum Distillation and Hydrotreating.

This system allows Indian re-refiners to produce API Group II/II+ base oils, reduce import dependency, and support the nation’s mission of building a stronger circular economy.

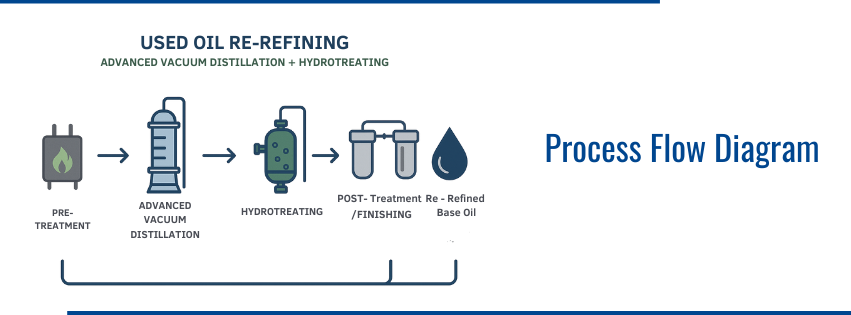

🔬 How the Technology Works: Step-by-Step

1. Pre-Treatment

Pre-treatment is the foundation of the re-refining process, ensuring that the used oil entering the system is clean, stable, and free from contaminants that could damage equipment or reduce process efficiency. Because used oil collected in India often contains water, dust, sludge, coolant, fuel residues, and metal particles, this stage plays a crucial role in preparing a uniform feedstock. Through mechanical separation, filtration, dehydration, and demetallization, impurities are removed, preventing fouling in heaters and protecting catalysts during hydrotreating. A properly executed pre-treatment stage significantly enhances yield, improves final product quality, and ensures smooth functioning of the advanced vacuum distillation and hydrotreating units.

This ensures cleaner feedstock, protects reactor catalysts, and stabilizes downstream processing.

2. Advanced Vacuum Distillation

Advanced vacuum distillation is the main separation stage where thermally stable, high-quality lube oil distillates are extracted under controlled low-pressure conditions. By operating at deep vacuum levels (2–5 mmHg), the system allows the oil to vaporize at much lower temperatures, preserving molecular integrity and preventing thermal cracking. Modern Indian plants use structured packing, heat-integrated systems, and energy-efficient furnace designs to achieve precise separation while minimizing fuel consumption. This stage isolates the key lube fractions that will undergo chemical purification in the hydrotreating reactor. The purity and quality of the distillate obtained here directly influence the performance of the final base oil.

Key benefits:

High separation efficiency

Preserved viscosity and molecular structure

Reduced fuel consumption through heat-recovery systems

High-purity distillate ideal for hydrotreating

States like Gujarat, Maharashtra, Tamil Nadu, Haryana, and Karnataka now operate modern vacuum distillation units with improved energy integration.

3. Hydrotreating

Hydrotreating is the core upgrading stage and the reason this technology produces API Group II/II+ base oils in India. In this reactor, the distilled oil is treated with hydrogen in the presence of specialized catalysts at controlled temperature and pressure. This process chemically removes sulfur, nitrogen, chlorine, aromatics, and degraded additive residues while also improving viscosity index, oxidation stability, and overall purity. Hydrotreating transforms the distillate into a highly stable, water-white base oil suitable for modern BS6 lubricants. Its ability to deeply purify and upgrade the oil is what sets this integrated system apart as India’s most advanced re-refining technology.

Under controlled temperature and pressure, the distillate is treated with hydrogen + catalysts (Ni-Mo or Co-Mo).

This step removes:

Sulfur

Nitrogen

Chlorine

Aromatic impurities

Oxidation byproducts

Odor-causing molecules

It improves:

Viscosity index (VI)

Thermal stability

Oxidation stability

Color (water-white clarity)

The final output is premium-grade API Group II/II+ base oil, suitable for BS6 engine oil formulations and industrial lubricants.

4. Post-Treatment / Polishing

The post-treatment or finishing stage is designed to give the hydrotreated oil its final clarity, brightness, and stability before it is supplied to the market. After chemical purification, the oil passes through polishing units, fine filtration, and optional dewaxing steps depending on application requirements. These finishing systems remove trace impurities, improve color, reduce odor, and enhance long-term storage stability. The end result is a premium-quality API Group II/II+ base oil that meets Indian and international performance standards for automotive and industrial lubricants. This final step ensures consistent quality, high customer acceptance, and strong commercial value.

The hydrotreated oil undergoes:

Adsorption polishing

Fine filtration

Optional dewaxing

Result:✨ Crystal clear, stable, long-life base oil ready for blending.

🌱 Advantages of This Technology for India

1. Reduces Dependence on Imported Base Oils

India imports a majority of its Group II oils.This technology enables domestic production of similar-quality base oils.

2. Supports India’s Circular Economy Mission

The process converts waste oil into reusable base oil, aligning perfectly with:

EPR mandates

Government sustainability goals

Resource recycling targets

It also reduces illegal burning and improper disposal.

3. Environmentally Safe & Regulatory Compliance

Hydrotreating Results In:

Very low emissions

Minimal hazardous waste

Cleaner effluents

No spent clay disposal challenges

It easily meets State Pollution Control Board norms.

4. Economically Efficient for Indian Re-Refiners

Features like:

Heat integration

Energy-efficient furnace designs

Automation & digital controls

lead to lower operating costs and higher yields.

5. Produces High-Grade Oils for Modern Indian Engines

Hydrotreated RRBO is suitable for:

BS6 passenger car motor oils

Heavy-duty diesel lubricants

Industrial hydraulic oils

Gear and compressor oils

This ensures compatibility with India’s rapidly modernizing automotive sector.

Conclusion

Hydrotreating integrated with Advanced Vacuum Distillation is the most advanced, environmentally sound, and economically impactful used oil re-refining technology available in India today.It supports national sustainability policies, meets modern lubricant quality standards, and significantly reduces the country’s dependency on imported base oils.

As India strengthens its circular economy and EPR framework, this technology will play a crucial role in shaping a cleaner, more efficient, and self-reliant lubricant ecosystem.